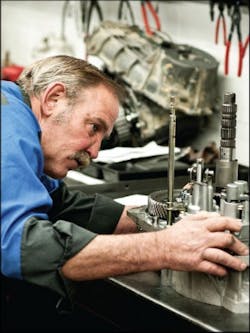

Chris Gerber is what you’d call a veteran of the repair industry; he’s a classic example of a technician who climbed the ranks to become a shop owner. But even though he’s clocked more than four decades worth of experience in the industry, that doesn’t mean he’s stopped trying to push his shop forward. As the owner of Transolution Auto Care in Missoula, Mont., Gerber has embraced new technology and makes an effort to stay not only on top of, but ahead of, the latest trends and technology in the industry.

I always ask my customers, remember the show The Jetsons and all the flying saucers? Well, we’re not too far off. Cars are changing unbelievably fast nowadays. The automotive industry changes every year. To adapt, you’ve absolutely got to be into reading and studying to keep up with the changes.

It’s a matter of staying current with the technology that’s out there and making sure your staff is educated, as well. I always like to stay on the edge of technology. I want to be the best shop in town, with the best equipment, and be ready to service our customers for whatever they need.

Shop Size:

5,400 square feet

Staff Size:

10

Annual Revenue:

$1.25 million

Average monthly car count:

450–500

I’ve always been interested in new technology because I’m an automotive junkie. I grew up in the industry and I’ve always been into it. When I first started out back in the 1970s, I worked with a great shop owner who would always ask, ‘Did you have anything to do with the cause, complaint or failure of the part?’ If you did, it’s your job to fix it.

I’ve adapted that to all my employees, too. No matter what comes in, we figure out how to correct the cause of the malfunction, rather than just replace parts. Many customers come in with a lot of drivability issues because they’ve gone from shop to shop, and those shops haven’t been able to figure out what the problem actually is.

Figuring out the root of the problem is something I really drill into my employees now. I get here before we open at 7:30 a.m. and, along with my two service writers, we input all the jobs that need to be done on a digital job board first thing in the morning. Then, if a customer brings in a car at 8 a.m., we always want to have the diagnostic information back to them by 10 a.m.

Striving to be the best at diagnosing has informed a lot of our technology investments, too. For example, a lot of cars today can be corrected by reflashes. For many years, we weren’t equipped to fix those errors, so we had to send the cars to the dealer. I decided that rather than sending the customers down the road, which takes away from shop profitability, I would invest in the necessary reflash equipment.

We had to purchase a J2534 tool, which hooks up to a dedicated computer station and downloads all of the information from the manufacturer. You can enter the vehicle identification number and find out what the vehicle needs and update it with the latest and greatest programs from the manufacturers.

Now we can update BMWs, Volvos, Chryslers, General Motors vehicles, and we can do a lot of things that other shops can’t because we have the knowledge and equipment to correct the problems. It was expensive and it was a big learning curve at the beginning to understand the program.

The first time I tried using it, I lost all of the information on the Chevrolet I was reflashing because my wireless Internet went down.

I watched a lot of videos of vehicles on how to reflash, I read everything I could get my hands on, and I was patient. It does take time, but the end result is that you’re a lot smarter and you’re able to help the customer out with services they otherwise would have to go elsewhere to get.

Similarly, I also recently upgraded to a VERUS scan tool from Snap-on. It’s a top-notch scanner that lets us do so much more than before. We can record drivability issues, print them out and show them to the customer.

Another feature we really like is the ability to record videos with it. Basically, once the tool is hooked up, you can bring up all the different inputs and outputs in the car and it will actually show the part working in a digital graphic. So you can watch the line go up and down as the transmission shifts, for example. If there’s a glitch, you’ll see a dash go up at the exact spot it glitches. That really helps us narrow down exactly where the issue is and we are then able to get a graph that shows precisely what the component is doing.

Again, learning everything your scan tool can do requires a lot of training. It’s like learning how to ride a bike. But if you don’t take the time to find out what all the programs do, then you’re just scratching the surface.

I spend time every day reading, learning and studying. People ask me all the time, how long did you go to school? I always say I never got out. Schooling is part of our lives every day.

I’m involved with a lot of industry associations, like the Automotive Transmission Rebuilders Association, International Automotive Technician Network, and Transmission Rebuilders Network Worldwide. There is a huge amount of information there, but you have to do the research.

I also make sure that all my staff members are involved in those groups. They become more productive because they have the tools at their fingertips to get the job done.

Every morning, I spend time going online, looking up how a component works, or studying the various manufacturers.

I also need to make sure that my employees know how to use the technology and are on top of the new trends. Every Thursday, I hold a weekly meeting over lunch for an hour. We go upstairs to the lunchroom and we either watch videos, talk about how the business needs to run, or work on SOPs. Everybody chips in to help and we decide how every job is going to be handled.

That’s how I get buy-in because they’re participating rather than me telling them what to do. It can be quite amazing how involved they get; they all want the shop to succeed and they all want to do good work.

The way I decide whether to invest in new technology or trends really comes down to demand. It’s really important for me to take the time to look at our market and figure out what’s coming or what our customers want.

For example, right now I’ve been looking into hybrid repair. We’re starting to see more of them because they’re getting out of manufacturer’s warranty, and it’s a huge investment. I have survey data that found there’s about 2,800 hybrids in our area. In a larger city, there could be as many as 30,000 hybrids, so I’m starting to prepare, but holding back a little bit.

My marketing and community efforts are also a way to get insight into my customers. I get to know their cars, the types of vehicles they like, what they want in a vehicle. That’s why I still spend part of my day talking to customers and getting to know them. Our ultimate goal is to help them and educate them so they can make the best decision for their car.