CollisionLink Plus: Customer Pain Points, a Changing Landscape, and a Better Way to Order Parts

OEC celebrated its 20th anniversary in 2020, a milestone for the company, certainly, but also a milestone for one of its earliest products, CollisionLink. It was time to evolve the product to help customers solve common pain points, even ones that didn’t yet exist… like conducting business in a landscape that felt like it was being shaped and reshaped almost every day.

New products and upgrades do not typically appear overnight. They take time, research, and strategic vision. The OEC CollisionLink product team, for example, began the initial phases of the CollisionLink Plus product enhancement and upgrade by working with collision repair facilities to identify customer pain points and to see how CollisionLink could be enhanced – or upgraded – to address these issues. The most common pain points customers identified included technician and administrative support shortages, inaccurate estimate data, and parts availability.

The overall development process required the team to prioritize trends and feedback to narrow the focus on a strategic roadmap, one with unique offerings for customers that aligns with the existing strengths of CollisionLink, while also addressing the key areas where customers identified problems.

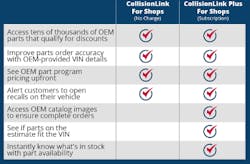

The CollisionLink team took their focused list of pain points, product outcomes and goals, and moved into the product enhancement and development phase. The team’s anticipated solutions soon took shape and included new product features, such as OEM Catalog Access, Parts Order Scrubbing by VIN, and better insights into parts availability. All of the new features were designed to improve customer experience and solve for those common pain points.

All that said, however, solving for any industry challenge is difficult at any point, but solving for issues as they are actively intensified by a global pandemic (and the still-lingering effects) is not a typical experience during product development.

Many of the existing pain points were soon intensified, creating greater urgency for collision repair facilities to find tools and solutions to help address common issues that now loom larger than ever over the industry. While it may not have grabbed front-page headlines, the collision repair industry was adjusting business strategies on the fly as much as any other market.

While the team initially set out to address common pain points, by launch time they were also working to decrease the lingering effects from the previous two years. Tech shortages and supply chain issues, for example, were not new issues, but in the changed landscape, CollisionLink Plus could alleviate the concerns that initially drove product development, while also providing support to repair facilities in uncertain times.

CollisionLink Plus is designed to help technicians work smarter and more productively, reducing the administrative burdens and allowing technicians to focus on proper vehicle repair. This improves customer service, enhances workflow, increases repair facility profitability, and lowers costs.

In conducting those early customer interviews and surveys, it became clear that time and information were two of the most valuable resources for a collision repair facility – and ones most would always like more of. To increase the availability of information, CollisionLink Plus offers OEM Catalog Access, helping to ensure that repairers order the right parts the first time by featuring detailed section images. This reduces the need for supplements, reordering, and returns, all avoidable obstacles technicians encounter during the repair process.

The upgrade also includes Part Scrubbing by VIN to help repairers get the right parts by flagging ones that don’t fit the vehicle, allowing users, based on OEM, to view alternative parts. Likewise, to further increase the already improved flow of information, CollisionLink Plus leverages the vast OEC dealer network and uses inventory data to provide information earlier in the ordering process, giving repair facilities access to parts inventories so they can know if certain parts are available and can manage jobs accordingly. This level of information allows for greater time management through effective scheduling and more informed decision making.

By making parts orders more accurate, CollisionLink Plus allows technicians to work more efficiently and reduces time-consuming administrative work (and redoing work), specifically supplemental orders, returns, and inaccurate data – all issues that take time away from vehicle repairs and negatively impact profitability.

With the new CollisionLink Plus upgrade, based on early estimates and analysis, collision repair facilities can reduce orders, supplements, and returns by over 30%, save repair facilities $2,300+ on admin costs, and increase gross profits by $800+ each month. All these benefits are available when CollisionLink users choose to upgrade to CollisionLink Plus, increasing access to information and improving time management.

The CollisionLink Plus launch recently took place in March 2022 with the support and backing of customer feedback, thousands of hours of development and research, and extensive product testing (the free CollisionLink enhancements first became available in spring 2021). The upgrade is being embraced by more shops than initial projections anticipated and the new tools give repair facilities a chance to thrive as they evolve (with the industry) to meet the demands of vehicle owners.

About the Author

Sponsored Content

The views and opinions expressed in this piece do not necessarily reflect those of 10 Missions Media and its associated brands.