Auto care is Nick Vaughn’s family legacy, but up until a few months ago, it wasn’t exactly included on his list of talents. His father, Dave, owns Vaughn’s Auto Repair in South Amherst, Ohio, and his entire family is involved in the shop in one way or another. Nick serves as the shop’s business consultant and although he was always involved in the business side of the company, he had very little experience actually working on cars.

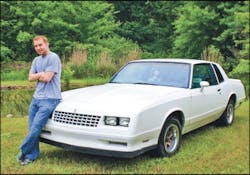

That is, until he purchased a 1983 Chevy Monte Carlo SS.

Car collecting is another trait that runs in the Vaughn family. Dave has more than 18 classic cars, and his brother has four old tow trucks. The ’83 Monte started Nick’s own collection. (After purchasing the Monte Carlo, he now has three vehicles that he hopes to pass down to his three children: the 1983 Monte Carlo, a limited edition Monte Carlo and a 1992 Ford F-150 Flareside.)

Nick says he always liked the look of Monte Carlos and knew it was what he wanted for his first project. It took him a long time, but he finally found what he was looking for when he stumbled across the ’83. Before he could buy it, though, he had to run it by his dad. Consulting each other is a rule in the Vaughn family, and since Dave is the expert, he was needed for a second opinion.

His father warned him that it would be no easy undertaking. The car, which had been in storage for two years, would be expensive and require a lot of time and effort. Luckily, time and effort was just what Nick was looking for. He was ready to learn.

When he was younger, his father discouraged him from working on cars and encouraged him to head to college, which he did. While Nick has never regretted this choice, he wanted the opportunity to get his hands dirty in the family trade.

“I want to learn how to do as much as I can on these things,” he says.

The car needed new springs and brakes, and needed air conditioning installed. The radio had been torn out so that also needed to be replaced and Bluetooth navigation was installed (keeping the car stock wasn’t important to Nick). Almost all of the original parts had to be replaced including the tie rods, brake lines and suspension.

The 305ci H.O. engine was given new spark plugs, wires and a distributor cap and has aftermarket components like headers, a new carburetor and air cleaner.

He and his father worked on the car together, and also brought in an extra set of hands, Nick’s 5-year-old son, Collin.

The three generations have been working on the car for a few months now. Since this was all new to Nick, the process was a lot of trial and error. His father would show him how to do it and then walk away, allowing him to get the experience he desired. Collin also picked up on a few things. The young apprentice can now open the hood of a car and point out and name many of the parts.

Although the work may be tedious and time consuming and the parts don’t come cheap, the time that Nick has spent with his father and his son restoring his car has been well worth it.

“Every moment feels like a memory being made,” he says. “Not just for me, but for my son as well.”